Safety is important in the world of footwear, and two key characteristics that are frequently mentioned for shoe safety are slip resistance and oil resistance. Many consumers may consider the terms “slip-resistant” and “oil-resistant” to be similar, bringing the question: Is oil resistant the same as slip resistant?

In this informative article, we will look into the distinctions and differences between these two important aspects of footwear in order to provide clarity and assist you in making informed decisions when it comes to selecting the right pair of shoes or boots.

What Is Slip Resistance?

Slip resistance, also called anti-slip, is critical in footwear safety. Slip resistance is a measurement of how well a shoe or boot can maintain traction on various surfaces.

It is specifically designed to reduce the risk of slipping, particularly in wet and slippery conditions. Usually, slip-resistant shoes have specialized outsoles with grip-enhancing patterns and materials.

What Makes Boots Slip-Resistant?

The factors that contribute to slip resistance are as follows:

Outsole Tread Design: The pattern and depth of the outsole tread have a large impact on how well a shoe grips the ground. Slip resistance is often associated with deeper and more complex patterns.

Outsole Material: The outsole material’s composition, such as rubber or synthetic compounds, affects its ability to grip surfaces. Certain materials are designed to provide superior traction in specific conditions.

Outsole Texture: The surface texture of the outsole can improve grip. Slip-resistant footwear frequently includes textured patterns or materials such as non-slip rubber.

Heel Design: The shape and material of the heel can also have an impact on slip resistance, particularly during heel strike.

Standards and Certifications for Slip-Resistant Shoes

There are standardized testing methods and certifications that have been established to ensure the effectiveness of slip-resistant footwear.

ASTM International and the European Union, for example, have established specific testing procedures to evaluate the slip resistance function on footwear.

The ASTM F2913 standard, established by the American Society for Testing and Materials (ASTM), provides guidelines for testing the slip resistance of footwear. The coefficient of friction (COF) between the shoe sole and various surfaces is measured using this standard in both dry and wet conditions.

ISO 20345 is an international standard that specifies safety footwear requirements. One of the performance parameters addressed by this standard is slip resistance. ISO 20345-compliant footwear has been tested and certified for slip resistance in accordance with the specified criteria.

While slip resistance focuses on surface traction, oil resistance is a specialized feature that refers to a shoe’s ability to prevent and withstand contact with oils and related substances.

Let’s continue to find out the truth about oil resistance.

What Is Oil Resistance?

Oil resistance refers to the ability of the shoe to withstand the harmful effects of oils, greases, and other hydrophobic substances. It is required in specific work environments where these substances are commonly around, such as industrial workplaces, kitchens, and automotive workshops.

For those oily work environments, normal shoes can absorb these substances, resulting in dirty appearance, decreased traction, material deterioration, etc. Oil-resistant footwear is intended to provide protection against these hazards.

What Makes Boots Oil Resistant?

Here are some factors that contribute to the oil resistance of boots:

Outsole Materials: Rubber compounds and specialized oil-resistant materials such as nitrile or neoprene are commonly used for outsoles to provide resistance to oils and other oil-based substances.

Tread Pattern: The outsole’s tread pattern can help with oil resistance by creating grooves that help disperse oil and improve traction. Deep, multi-directional treads are frequently used to prevent oil buildup below the sole, reducing the risk of slips and falls.

Lug Design: Oil-resistant boots may have lugs or cleats on the outsole. These edges increase traction and stability by providing additional grip and preventing oil accumulation.

Chemical Treatments: Specialized finishes or coatings will be applied to boots to improve their oil resistance. These treatments form a barrier on the boot’s surface, reducing oil absorption and making cleaning easier.

Oil-Repellent Agents: Adding oil-repellent agents in the manufacturing process of shoes can add an extra layer of protection against oil penetration.

Standards and Certifications for Oil-Resistant Shoes

There are various organizations, including ASTM International, which have established specific tests and certifications to ensure that footwear meets the necessary oil-resistant standards.

Such as ASTM D596. The American Society for Testing and Materials (ASTM) has established the ASTM D5963 standard, which specifically evaluates the oil resistance of footwear materials.

ISO 20344 is another global standard that specifies personal protective equipment, including footwear. It includes oil resistance testing criteria as well as other performance parameters such as slip resistance.

These tests assess the shoe’s ability to withstand the damaging effects of oils while maintaining its integrity. When purchasing oil-resistant footwear, look for relevant certifications to ensure its effectiveness in oil-prone environments.

It can ensure that your shoes maintain their performance and durability for a longer period despite exposure to these substances.

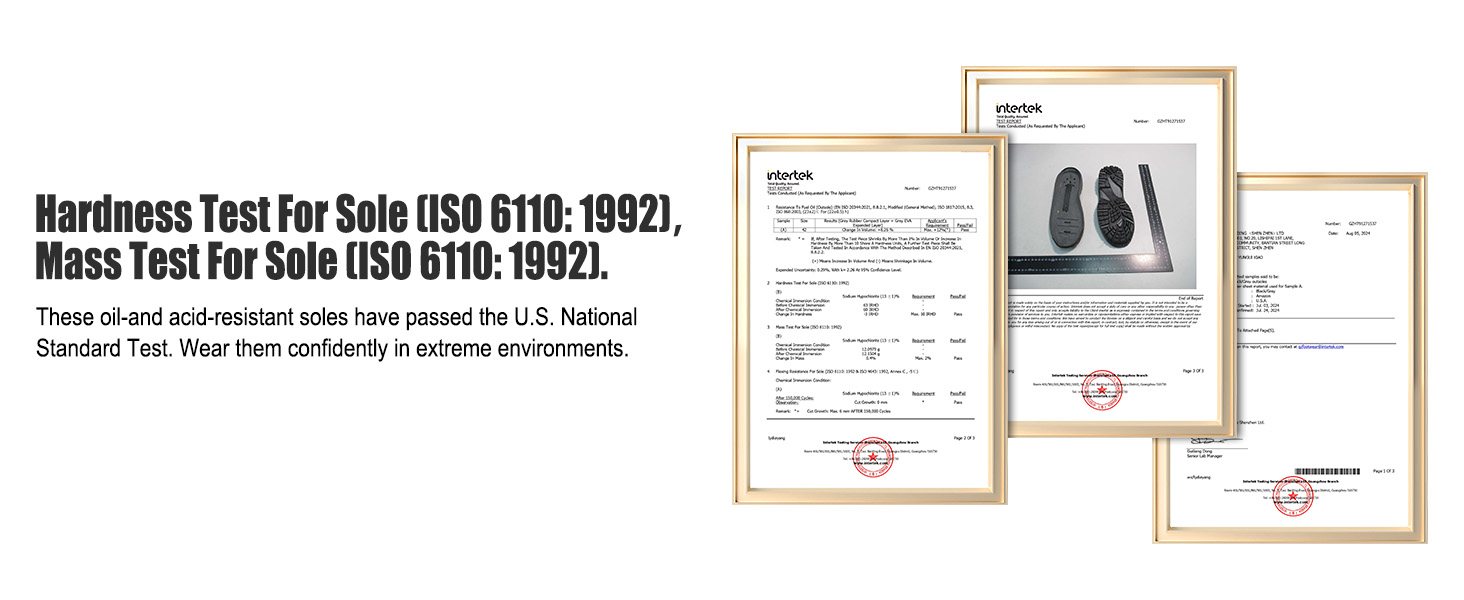

Kalkal chemical-resistant work boots have passed the test

Key Differences Between Oil and Slip Resistance

To determine whether oil resistance and slip resistance are the same thing, it’s important to look at their primary purpose, the situations in which they work, and their respective benefits and limitations. Let us look at the differences between these two critical characteristics:

Primary Purpose:

Slip Resistance: The primary goal of slip resistance is to provide traction and grip on different surfaces in order to prevent slips and falls. Slip-resistant shoes are made to perform well in a variety of conditions, such as wet, oily, or uneven surfaces.

Oil Resistance: On the other hand, oil resistance is concerned primarily with protecting footwear from the corrosive effects of oils, greases, and hydrophobic substances. The primary goal is to ensure that the shoe’s integrity and materials are unaffected by these substances.

Workplace Situations

Slip Resistance: Slip-resistant footwear is essential in environments where people may come into contact with slippery surfaces due to moisture, debris, or uneven terrain. It is especially important in industries such as hospitality, healthcare, and construction, where slips and falls can result in serious injuries.

Oil Resistance: Oil-resistant footwear is essential in environments where oils, greases, and other similar chemicals frequently occur, such as factories, vehicle repair shops, and kitchens. These substances can degrade standard footwear, raising slip hazards as well as safety and durability concerns.

Slip Resistant vs Oil Resistant: How to Choose?

When selecting footwear, it is critical to consider a variety of factors to ensure that your shoes meet your specific needs. Some of the shoes may only have anti-slip or anti-oil features, but some of the shoes may have both of them.

Consider the following factors as you make your decision:

Specific Purpose:

Consider where and how you’ll be wearing the footwear. If you work in an environment where there are oils and slippery surfaces, choose shoes that are both oil- and slip-resistant. Choose footwear that is appropriate for the conditions you will encounter while participating in recreational activities.

Lifestyle Factors:

Your daily activities and lifestyle can influence your footwear requirements. If you spend a lot of time outside, you may need slip-resistant hiking boots that can handle wet terrain. Take into account how your footwear fits into your daily routine.

Personal Preferences

Consider your personal shoe style, design, and comfort preferences. While safety features are important, finding footwear that matches your preferences is also important for long-term satisfaction.

Budget Considerations

Determine your footwear budget. While high-quality, specialized footwear can be costly, it’s critical to find a balance between price and features that meet your needs.

Conclusion

In sum, oil resistant and slip resistant are not the same as they address different aspects of safety. Although these terms may appear similar, they refer to different properties that serve different purposes.

Slip-resistant footwear performs excellently in a variety of wet conditions, providing traction on various surfaces. It may not, however, provide the same level of oil resistance as oil-resistant footwear.

Oil-resistant footwear provides excellent protection against oils and other similar substances. It may not, however, provide the same level of traction on slippery surfaces as slip-resistant footwear.

For choosing working boots, you may also like:

10 Best Work Boots for Plumbers – Reviews, Pros&Cons

8 Best Logger Boots for Maximum Safety & Comfort

Leave a reply